|

|

Мастерская Марка Террела

Взято с mtknives.com

I work out of a 1200 square foot shop that used to be a storage shed and carport (which we enclosed).

My shop is divided into 3 rooms, one is the dry room (immediately below), the other is my grinding room,

where all the dirty work goes down.

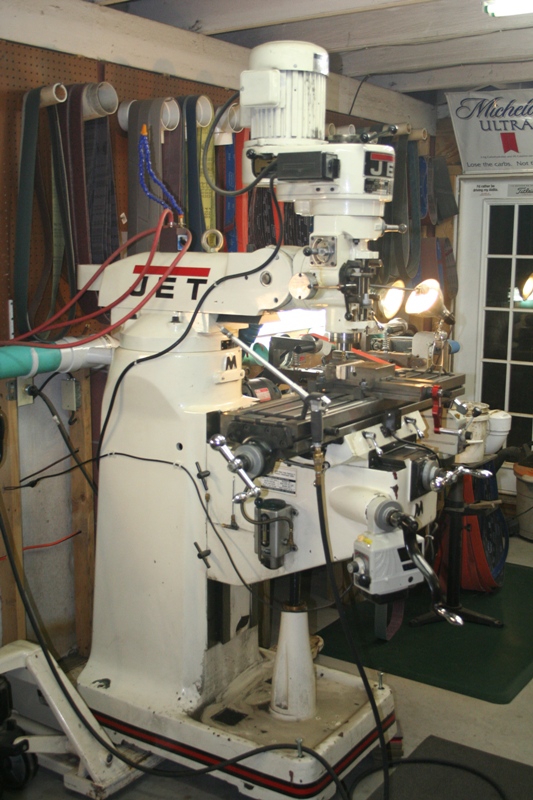

I use KMG grinders for my bevel work and blade grinding. 2 of these are in shop, and I also use a 4 X 36

for handle work. All of these are set up above a 3 horsepower dust collection system that sends particles

and exhaust outward of the shop. This is a must for work with carbon fiber and G10.

The shop has recently undergone some major renovations and upgrades. All the wiring was replaced and

everything was separated to dedicated lines/circuits. I also replaced the induction fan in my dust

collector/exhaust unit with a specialized fan that has about 40% more pull. The motor and housing was

removed from the floor and is now mounted upside down on the grinder bench.

I finally got my surface grinder up an running... It's a old Norton Automatic 6 X 18... It's got power feed for the X & Y axis and it's quickly becoming the most valuable tool in my shop.

I moved the aircompressor from themain room to aseparate room. I also ran lines for air connects throughout the shop.

Мy Jet JTM-2 mill. It's become a great addition to my shop and I'm getting more proficient with it. It's primarily used on folders.

Мy wood stabilizing an processing room. I just recently converted this from a storage room.

Some comprehensive photos of the shop. I try to keep it as open and easy to move around as possible. It is imperative, with all the machinery, that the surroundings are easy to navigate. I am a pretty organized person as I've found that it greatly reduces my production time when things are easier to find.